Additive Manufacturing with Metal Powders Market Growth Opportunities and Forecast till 2032

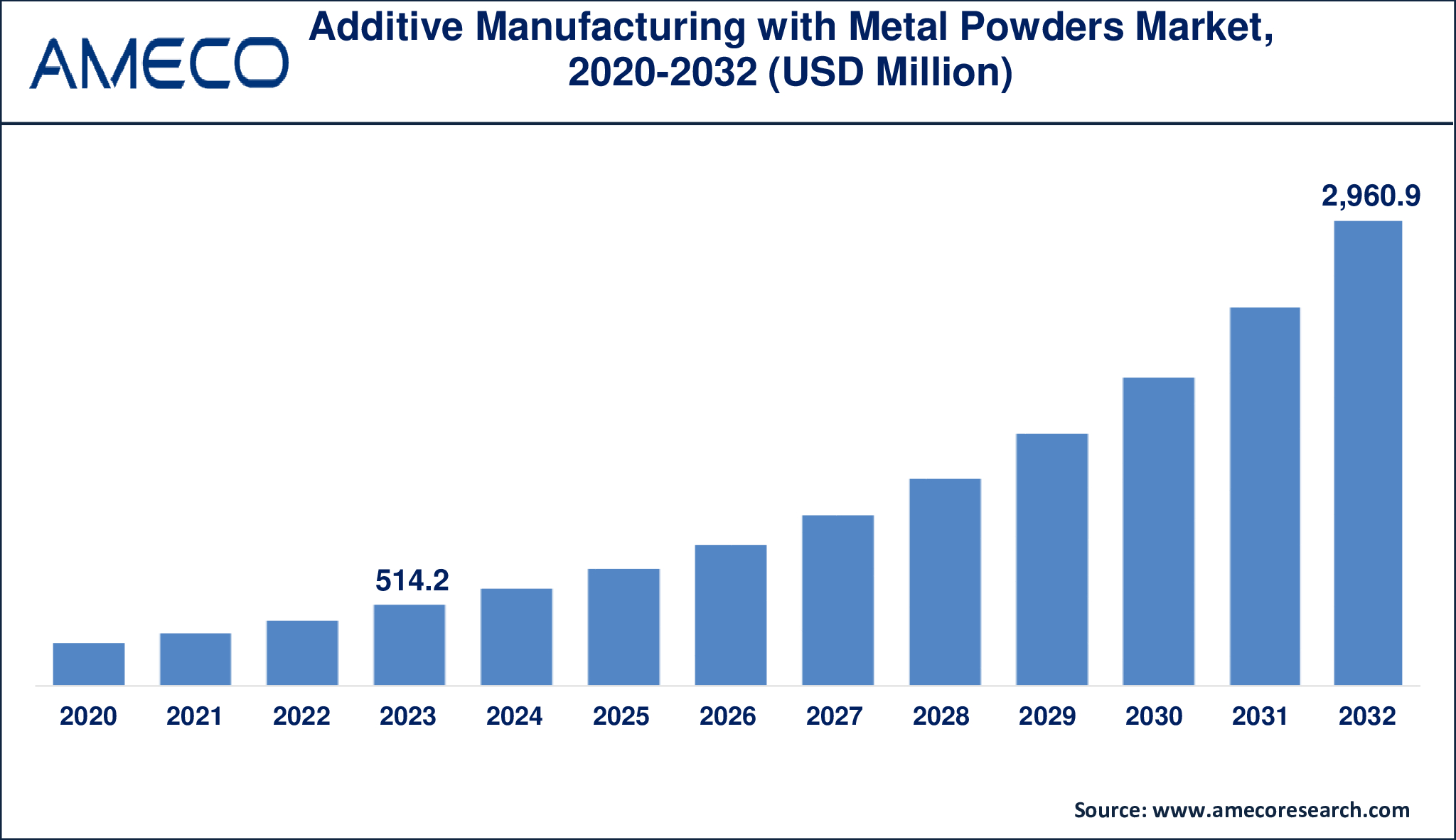

The Global Additive Manufacturing with Metal Powders Market Size was valued at USD 514.2 Million in 2023 and is anticipated to reach USD 2,960.9 Million by 2032 with a CAGR of 21.7% from 2024 to 2032.

Metal additive manufacturing (or metal 3D printing) is the technique of creating a three-dimensional, solid item of almost any shape or design from a computer-generated structure. The method commonly employs technologies such as selective laser melting (SLM), electron beam melting (EBM), or direct metal laser sintering (DMLS), in which a laser or electron beam selectively melts and fuses metal particles layer by layer based on a computer design file. This process enables the fabrication of very complicated and detailed parts, which would be difficult or impossible to make with typical subtractive manufacturing methods.

This manufacturing technology is very useful for making lightweight components with high strength-to-weight ratios, which are commonly utilized in the aerospace, automotive, and medical sectors. The supply chain for metal powders used in additive manufacturing (AM) is now expanding exponentially, bringing with it new powder suppliers, powder manufacturing processes, and more rivalry. It is now widely employed in the car industry, aerospace industry, medical sector, and educational institutions. AM products with uniform and predictable attributes require repeatable input materials (e.g., metal powders), which necessitates standardized powder property measuring procedures.

|

Parameter |

Additive Manufacturing with Metal Powders Market |

|

Additive Manufacturing with Metal Powders Market Size in 2023 |

US$ 514.2 Million |

|

Additive Manufacturing with Metal Powders Market Forecast By 2032 |

US$ 2,960.9 Million |

|

Additive Manufacturing with Metal Powders Market CAGR During 2024 – 2032 |

21.7% |

|

Additive Manufacturing with Metal Powders Market Analysis Period |

2020 - 2032 |

|

Additive Manufacturing with Metal Powders Market Base Year |

2023 |

|

Additive Manufacturing with Metal Powders Market Forecast Data |

2024 - 2032 |

|

Segments Covered |

By Form, By Material, By Technology, By Application, and By Region |

|

Additive Manufacturing with Metal Powders Market Regional Scope |

North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

|

Key Companies Profiled |

3D Systems, Ametek Inc., Arcam AB, BASF SE, Erasteel Metallpulver GmbH, GE Additive, GKN Hoeganaes Corporation, Praxair Surface Technologies, Inc., Renishaw, Sandvik AB, SLM Solutions Group AG, and Stratasys. |

|

Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Regulation Analysis |

Additive Manufacturing with Metal Powders Market Dynamics

Material developments, process enhancements and the additive manufacturing business forging relationships with established industry are all playing a role in developing the metal powder sector of additive manufacturing. With a demand for light-weight and high performance components along with an increase in efficiency, the air bearing market is expected to witness robust growth throughout global manufacturing lines hierarchy changing significantly over following years. Even with this expansion, the longstanding issues around cost and quality control as well as post-processing processes make clear that technical development in these areas continue to be necessary.

The demand for intricate, customized parts in industries such as aerospace, automobile and healthcare are the key factors driving market growth. These are the sectors that require components with a high strength-to-weight ratio, which metal additive manufacturing offers. Furthermore, the reduced material waste and capacity to swiftly prototype and create small batches add to the market's attraction, hastening its adoption.

However, the high cost of metal powders and the complex equipment necessary for additive manufacturing pose substantial impediments, especially for small and medium-sized businesses. Quality control and post-processing problems provide further barriers to wider use. Nonetheless, these constraints provide potential for innovation, notably in generating low-cost materials, enhancing quality assurance systems, and fine-tuning post-processing techniques. As technology advances, it is anticipated that new opportunities for additive manufacturing using metal powders will emerge, leading to expanded applications and market growth.

Global Additive Manufacturing with Metal Powders Market Segment Analysis

Additive Manufacturing with Metal Powders Market By Form

· Powder Bed

· Blown Powder

· Others

According to the additive manufacturing with metal powders industry analysis, the powder bed segment has historically gathered the largest market share in the additive manufacturing with metal powders market. This is primarily due to its widespread use in technologies like selective laser melting (SLM) and direct metal laser sintering (DMLS), which are popular for producing high-precision and complex metal parts. The ability of Powder Bed systems to create fine details and complex geometries with a high degree of accuracy has made it the preferred choice in industries such as aerospace, automotive, and medical, driving its dominance in the market.

Additive Manufacturing with Metal Powders Market By Material

· Alloy

· Aluminium Nitride

· Aluminium Oxide Powder

· Magnesium

· Molybdenum

· Precious

· Silicon Carbide

· Stainsteel Steel

· Tungsten

· Tungsten Carbide

· Zirconium

· Zirconium Dioxide

· Others

In 2023, the alloy category dominated the additive manufacturing using metal powders market. Alloys, particularly those based on titanium, nickel, and cobalt-chromium, are frequently utilized owing to their superior mechanical qualities, which include high strength, corrosion resistance, and heat tolerance. These qualities make alloys particularly desirable in areas such as aerospace, automotive, and medical implants, where extreme-condition performance is critical, contributing to their market dominance.

Additive Manufacturing with Metal Powders Market By Technology

· Selective Laser Melting (SLM)

· Electron Beam Melting (EBM)

· Others

The selective laser melting (SLM) category has the largest market share in the additive manufacturing with metal powders industry. SLM is generally regarded for its ability to make high-precision, complex metal components with great mechanical qualities, making it the preferred technology in industries such as aerospace, automotive, and healthcare. Its ability to operate with a wide range of metal powders, along with its superior precision and precise resolution, has helped it to dominate the industry.

Additive Manufacturing with Metal Powders Market By Application

· Automotive Industry

· Aerospace Industry

· Healthcare & Dental Industry

· Others

The aerospace Industry is predicted to lead the additive manufacturing using metal powders market between 2024 and 2032. This is owing to the aerospace industry's high need for lightweight, high-performance components that can resist harsh environments, which additive printing using metal powders is ideally equipped to provide. The capacity to build complex, bespoke components with decreased material waste and quicker lead times makes it particularly advantageous in aircraft applications, guaranteeing its market leadership during this period.

Additive Manufacturing with Metal Powders Market Regional Analysis

The Asia-Pacific area emerges as the market leader in additive manufacturing using metal powders, with a 38% share. This development trajectory is largely driven by rising demand for metal powder-based additive manufacturing in important industries such as aerospace, automotive, and healthcare. China, India, and Southeast Asian countries such as Korea, Thailand, Malaysia, and Vietnam are experiencing an increase in the manufacture of metal powder-based additive manufacturing components. This spike is likely to drive market development in the area throughout the forecast period.

North America was a major producer of metal powder additions, particularly the United States and Canada. The aerospace, automotive, and healthcare industries are widely represented in the region, and they have utilized metal additive manufacturing technology to quickly build complicated components through prototyping. Europe leads the globe in industrial production, including nations like Germany, France, and the United Kingdom. The aviation, automotive, and pharmaceutical industries in the region have showed a strong interest in additive manufacturing. The emphasis on research and development has played a significant role in the growth of this industry.

Additive Manufacturing with Metal Powders Market Leading Companies

The additive manufacturing with metal powders market players profiled in the report is 3D Systems, Ametek Inc., Arcam AB, BASF SE, Erasteel Metallpulver GmbH, GE Additive, GKN Hoeganaes Corporation, Praxair Surface Technologies, Inc., Renishaw, Sandvik AB, SLM Solutions Group AG, and Stratasys.

Additive Manufacturing with Metal Powders Market Regions

North America

· U.S.

· Canada

Europe

· U.K.

· Germany

· France

· Spain

· Rest of Europe

Latin America

· Brazil

· Mexico

· Rest of Latin America

Asia-Pacific

· China

· Japan

· India

· Australia

· South Korea

· Rest of Asia-Pacific

Middle East & Africa

· GCC

· South Africa

· Rest of Middle East & Africa