Aluminum Extrusion Market Growth Opportunities and Forecast till 2032

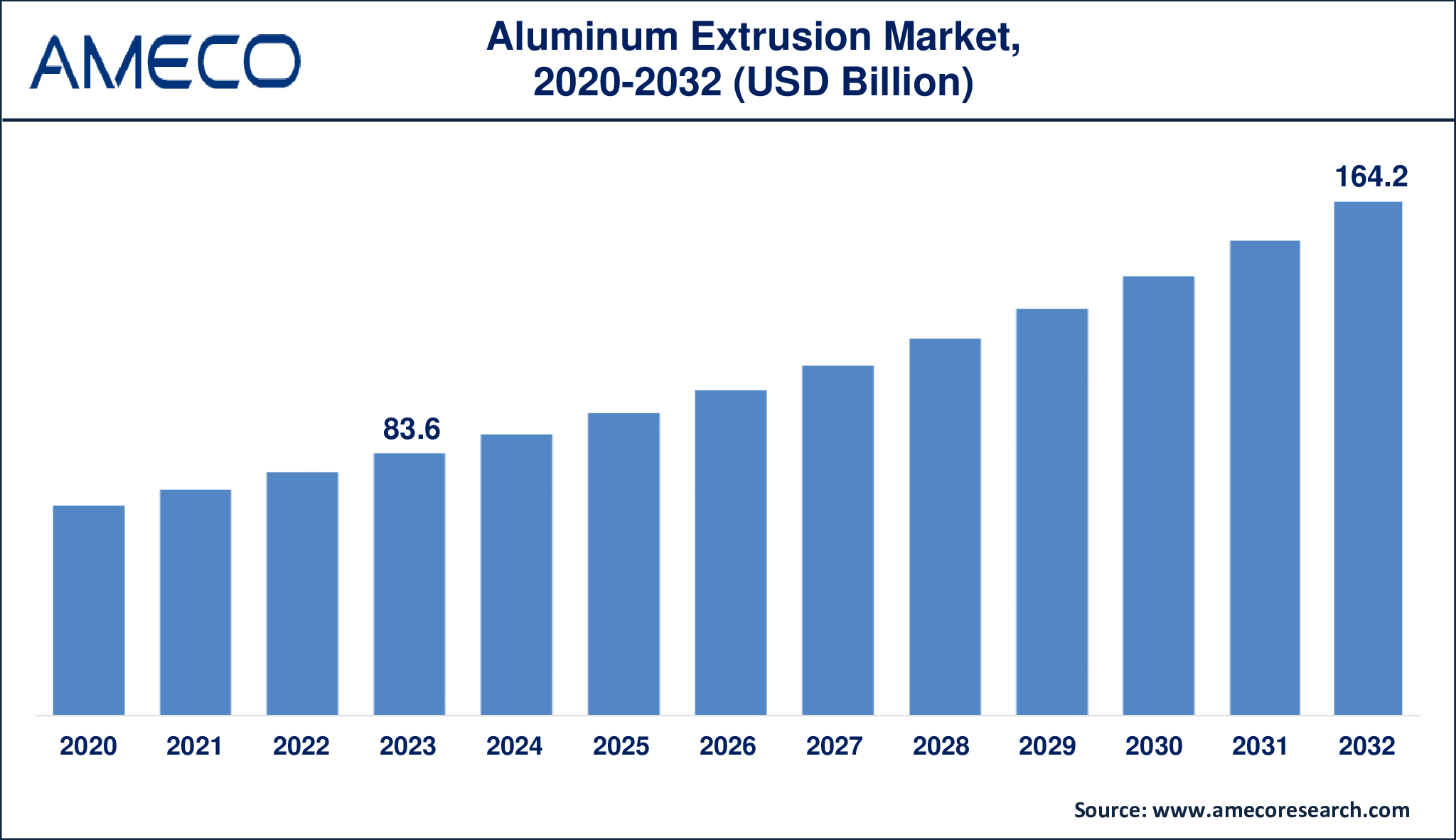

The Global Aluminum Extrusion Market Size was valued at USD 83.6 Billion in 2023 and is anticipated to reach USD 164.2 Billion by 2032 with a CAGR of 7.8% from 2024 to 2032.

Aluminum extrusion is a technique in which aluminum alloy in the state of either as preformed or directly melted is compelled to traverse through one or more die having cross sectional profile. This technique converts aluminum into adaptable profiles utilized in diversified sectors due to its light weight, solidity, and immunes to rust. The process involves three main steps: the conditioning of the aluminum billet, the application of pressure on it by the die and the subsequent cooling or finishing of the extruded part. These profiles can in turn be designed for various purposes, simple regular shapes such as rods and tubes, to complex shapes as may be demanded in the automobile, construction and aerospace industries respectively.

The advantages of the application lie with the flexibility and the relatively lower costs of aluminum extrusion. It enables the fabrication of a wide range of shapes with good mechanical properties while at the same time being lightweight, making fabrication for structures that require high strength-to-weight ratio feasible. Moreover, non-ferrous, especially, aluminum alloys has good conductive ability, able to be recycled, and has a wide range of choices of surface treatments such as anodizing or powder coating. That is why the degree of popularity of extruded aluminum products grows along with the increasing concern about sustainability and energy saving throughout various industries: this contributes to new technological advancements and modifications in the material’s compositions.

|

Parameter |

Aluminum Extrusion Market |

|

Aluminum Extrusion Market Size in 2023 |

US$ 83.6 Billion |

|

Aluminum Extrusion Market Forecast By 2032 |

US$ 164.2 Billion |

|

Aluminum Extrusion Market CAGR During 2024 – 2032 |

7.8% |

|

Aluminum Extrusion Market Analysis Period |

2020 - 2032 |

|

Aluminum Extrusion Market Base Year |

2023 |

|

Aluminum Extrusion Market Forecast Data |

2024 - 2032 |

|

Segments Covered |

By Product, By Application, and By Region |

|

Aluminum Extrusion Market Regional Scope |

North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

|

Key Companies Profiled |

Alupco, Arconic Corp., Bahrain Aluminum Extrusion Company, Constellium N.V., Gulf Extrusions Co. LLC, Hindalco Industries Ltd., Kaiser Aluminum, Norsk Hydro ASA, and QALEX. |

|

Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Regulation Analysis |

Aluminum Extrusion Market Dynamics

The global market for aluminum extrusion is growing at a steady rate due to the rising applications of light weight and corrosion resistant products in numerous end use segments. An important reason as to why aluminum extruded products are gaining popularity is the fact that they are very strong for their weight, which is very important in big constructions and buildings where there is need for extra strength at the same time when weight is of concern. Besides the light weight construction, aluminum extrusions have high corrosion resistance, thus can be applied in various environmental conditions. This property not only improves the durability of the product but also cuts the overall maintenance cost where the product is employed in Industrial applications thus boosting the market demand.

Nevertheless, when it comes to threats, market is rather vulnerable to such factors as high initial investments and low production rates. Establishing a manufacturing unit for aluminum extrusion entails huge capital investment on equipment and plant such as extrusion press. Moreover, the extrusion process is relatively slower than other processes and thus does not allow for continuous production. These factors might become the impediments to the market growth, thereby, causing the variations in the market’s development.

The increasing use of aluminum in electric vehicles (EVs) has turned out to be one of the key opportunities for the aluminum extrusion market. Aluminum is the preferred material in the production of EVs due to its strength to weight ratio, which is particularly important if the manufacturers want to extend the battery life and, therefore, the range of the vehicle. In addition, the improved thermal conductivity of aluminum improves battery casings and heat sink designs for better thermal regulation and safety. The International Energy Agency has estimated that sales of EVs in 2023 were 3.5 million more than 2022, an increase of 35 percent on the previous year. Battery electric vehicles made up of about 18 % of all cars sold in 2023, 14% in 2022 and a mere 2% in 2018. These strong growth trends for the EV market should persist in the future, which will in turn help to increase the demand for aluminum extrusions.

Global Aluminum Extrusion Market Segment Analysis

Aluminum Extrusion Market By Product

· Shapes

· Rods & Bars

· Pipes & Tubes

According to the aluminum extrusion industry, the shapes segment accounted for the highest market share by product type in 2023. This is mainly because custom extruded shapes are used in construction, automotive and aerospace industries for structural parts, frames of doors and windows and light weight auto parts respectively. The ability of Shapes to satisfy particular design needs and the high strength to weight ratio has seen this product type become the most popular, thus propelling its market dominance.

Aluminum Extrusion Market By Application

· Building & Construction

· Automotive & Transportation

· Consumer Goods

· Electrical & Energy

· Others

According to the aluminum extrusion market forecast, the building & construction segment is expected to lead the market from 2024 to 2032. This is due to increase in demand for lightweight, durable and corrosion resistant material in infrastructural developments and urbanization activities globally. Aluminum extrusions find application in window frames, curtain walls, roofing structures and other structural members because of their high strength to weight ratio and versatility of shapes. Also, the increasing consciousness of green building and energy efficient construction activities help in the increased usage of aluminum extrusions, as they can be recycled.

Aluminum Extrusion Market Regional Analysis

From the report it is evident that the Asia-Pacific region dominated the market share in the aluminum extrusion market. The automotive industry in this region is steadily growing, Japan and South Korea are acknowledged as car producers and China is predicted to become the largest auto market in the world. The need for light and efficient vehicles due to the ever rising environmental standards has greatly enhanced the aluminum extrusion products. Further, the Asia-Pacific region is a manufacturing and technology center, sectors that incorporate aluminum extrusions in a number of applications.

Europe was the second largest region in the aluminum extrusion market with large market share in 2023. Praised as the world’s leading industrial region, Europe hosts a wide variety of industries with the automotive industry occupying a leading position. This strong industrial base coupled with the growing use of aluminum extrusions for light weight and energy efficient applications point to the regions significant contribution to market growth.

Aluminum Extrusion Market Leading Companies

The aluminum extrusion market players profiled in the report is Alupco, Bahrain Aluminum Extrusion Company, Arconic Corp., Constellium N.V., Hindalco Industries Ltd., Gulf Extrusions Co. LLC, Kaiser Aluminum, QALEX, and Norsk Hydro ASA.

Aluminum Extrusion Market Regions

North America

· U.S.

· Canada

Europe

· U.K.

· Germany

· France

· Spain

· Rest of Europe

Latin America

· Brazil

· Mexico

· Rest of Latin America

Asia-Pacific

· China

· Japan

· India

· Australia

· South Korea

· Rest of Asia-Pacific

Middle East & Africa

· GCC

· South Africa

· Rest of Middle East & Africa