Automotive Lightweight Materials Market Growth Opportunities and Forecast till 2032

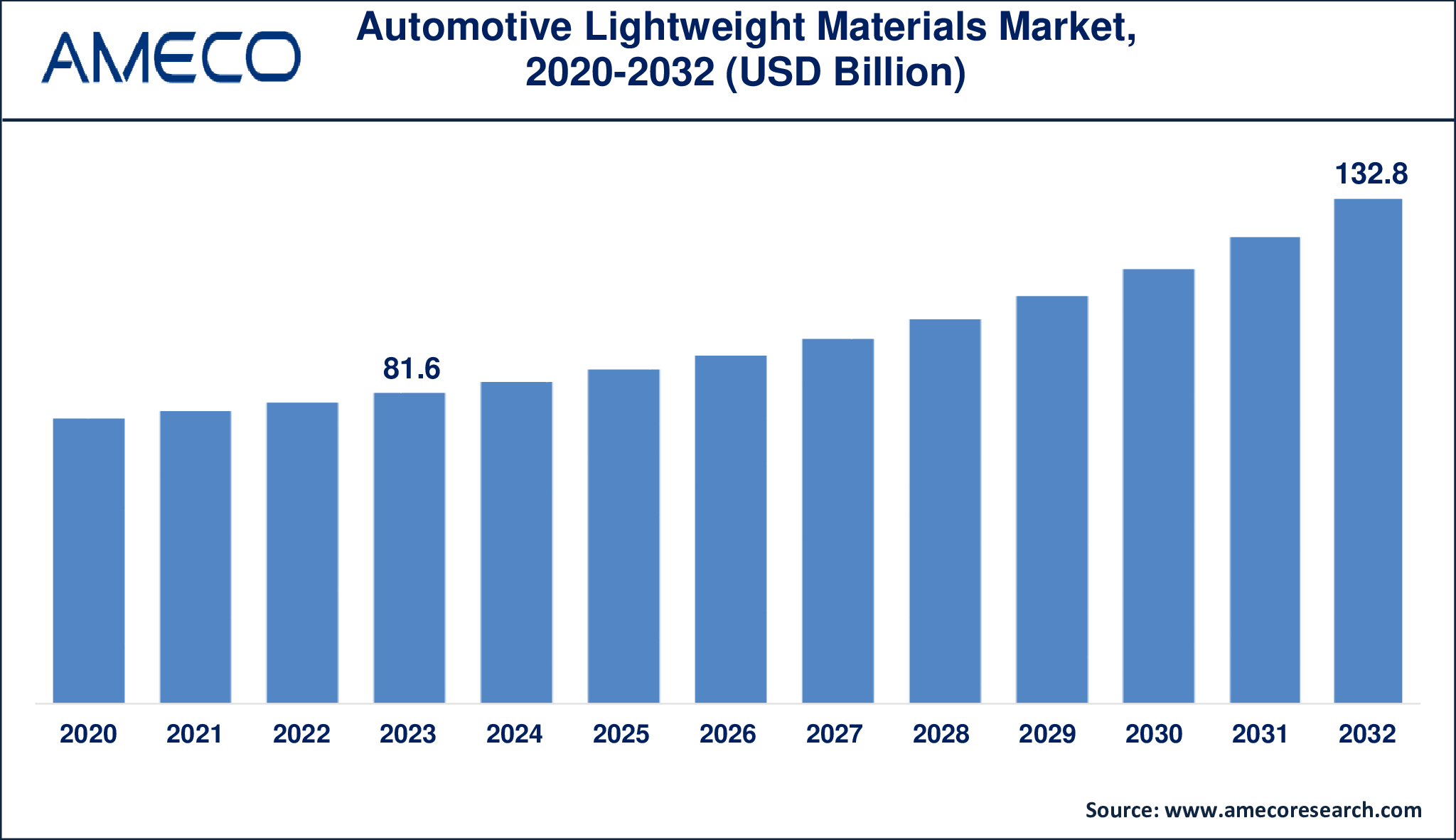

The Global Automotive Lightweight Materials Market Size was valued at USD 81.6 Billion in 2023 and is anticipated to reach USD 132.8 Billion by 2032 with a CAGR of 5.8% from 2024 to 2032.

The automotive industry is undergoing major changes to adapt to new environmental norms at the moment. Environmental activist groups and non-governmental organizations (NGOs) have for a long time accused the sector of contributing to greenhouse emissions, with road transportation accounting for about a quarter of the entire emissions. This scrutiny has led to increased usage of light weight materials in automobile production. The application of light weight materials in the vehicles plays a significant role especially in the achievement of reduced body weight. A lighter vehicle consumes less fuel thus improving on the efficiency of the car. For instance, the removal of a 10% of a car’s weight can promote the fuel efficiency by 6% to 10%.

The efforts to lose weight have become a paramount goal of the automotive industry since it has a direct impact on fuel consumption and, therefore, environmental friendliness. Among the materials being embraced is aluminum which is lighter than the normal steel by a big margin. Aluminum can be used in vehicle construction to greatly decrease the vehicle’s weight while maintaining the strength. Carbon fiber is another type of lightweight material that also enjoys growing popularity in the automotive field. Carbon fiber has a better strength to weight ratio than aluminum and has even more weight saving possibilities, which makes it the material of choice for performance and environmentally friendly vehicles. Other materials including magnesium, titanium and some high end composite structures consisting of carbon fiber reinforced with other materials are also being incorporated into automobile structures. These materials allow such manufacturers to deliver lighter weights which in return are strong enough to support the shift towards more sustainable transport solutions.

|

Parameter |

Automotive Lightweight Materials Market |

|

Automotive Lightweight Materials Market Size in 2023 |

US$ 81.6 Billion |

|

Automotive Lightweight Materials Market Forecast By 2032 |

US$ 132.8 Billion |

|

Automotive Lightweight Materials Market CAGR During 2024 – 2032 |

5.8% |

|

Automotive Lightweight Materials Market Analysis Period |

2020 - 2032 |

|

Automotive Lightweight Materials Market Base Year |

2023 |

|

Automotive Lightweight Materials Market Forecast Data |

2024 - 2032 |

|

Segments Covered |

By Material, By End Use, By Application, and By Region |

|

Automotive Lightweight Materials Market Regional Scope |

North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

|

Key Companies Profiled |

Alcoa Corporation, ArcelorMittal, BASF SE, LyondellBasell, Novelis Inc., Owens Corning, POSCO, Stratasys Ltd., Tata Steel, and Toray Industries, Inc.. |

|

Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Regulation Analysis |

Automotive Lightweight Materials Market Dynamics

One of the most important trends that can be mentioned as the factor influencing the increased popularity of lightweight materials is the focus on decreasing fuel consumption in automotive industry. The use of lightweight materials in the development and manufacturing of automobiles is one of the most successful approaches of enhancing the general fuel economy. Leveraging high performance materials like composites, aluminum and high strength steel alloys the weight can be slashed substantially without compromising on structure strength or safety.

The principle behind this approach is straightforward: smaller cars consume less energy to get moving and hence use less fuel as well as emitting less greenhouse gases. Light material integration enables car manufacturers to produce lightweight cars that meet the demands of traditional gasoline cars and modern electric and hybrid cars. In traditional vehicles, weight reduction results directly with fuel economy hence allowing manufactures to meet regulatory requirements. For electric vehicles (EVs), weight loss enables better battery utilization and consequently the driving range, which is one of the most critical determinants in consumer acceptance and EV market penetration. Therefore, there is a steady increase in the demand for automotive lightweight materials on the global market as the industry looks for better techniques to attain optimal performance and fuel economy while meeting environmental concerns.

The global change in trends towards better fuel economy and reduced emissions has emerged as the major driving force behind the automotive industry transformation. As a result of the awareness on environmental degradation caused by vehicles, governments of the world have placed strict rules that force car makers to employ strategies to reduce vehicle weight among others to achieve better fuel consumption. In the United States, new fuel efficiency standards, known as the Corporate Average Fuel Economy (CAFE) standards, set an industry average of 54.5 miles per gallon by 2025. Likewise, the European Union has set its goals high by providing legal requirements that the new vehicles should not emit more than 95 g CO2 per km by 2021. These regulatory frameworks have quite notably raised the bar for lightweighting, so for example, the use of aluminum, high strength steel and carbon fiber composites. As they offer the opportunity to achieve significant weight savings without affecting safety or handling, these materials are vital in helping auto makers adhere to ever stricter efficiency and emissions regulations imposed by world-wide legislatures.

The use of lightweight materials in automobile industry is restricted due to high cost of production; costs such as the cost of carbon fiber and some new age composite materials. Such materials necessitate unique working methods and intricate manufacturing procedures, which greatly increase costs. Consequently, these solutions may be met with caution by manufacturers, who prefer focusing on the costs rather than the performance or the longevity of the product. The high first cost of implementing lightweight materials can also slow down their penetration in the industry even more.

Market factors also affect the market to a great extent and the most important of them is the economic factors. For example, high performance materials like carbon fiber may go for as high as USD 20-40 per kilogram; while steel, a standard material, can cost as low as USD 0.75-2 per kilogram. Such a wide gap in costs presents a significant challenge to the widespread adoption of light weight materials, especially in segments of the automotive industry that are sensitive to costs.

Global Automotive Lightweight Materials Market Segment Analysis

Automotive Lightweight Materials Market By Material

· Metals

· Composites

· Plastics

· Elastomers

The metals segment is expected to dominate the growth of automotive lightweight materials market, thus contributing to 52% of the overall revenue in the coming years. This dominance is due to the increased use of light metals including aluminum, titanium, magnesium, and high strength steel in vehicle structures and vehicle frame, particularly in electric and heavy vehicles. The overall demand for metallic materials is anticipated to rise because of their durability in structural parts such as chassis, passenger compartment frames, underbody floors and instrument panels. Metallic structures increase vehicle stability and durability and play a very crucial role with regard to the general structure of vehicles.

Automotive Lightweight Materials Market By End Use

· Passenger Cars

· LCV

· HCV

The passenger cars segment remains the largest market segment due to its significance in the automotive business. This dominance is due to the fact that the segment aims at satisfying some consumer demands and legal standards regarding fuel economy and emissions. These objectives are realized through lightweighting by optimizing vehicle weight, achieving better fuel efficiency and lowering pollution. Also the focus on passenger cars is not only on structurality but on design and thus using alloys, composites and polymers allows creating visually appealing profiles of car without losing safety or performance. This synchronization with the consumer trends is a clear indication of why lightweight materials are highly valued within the passenger car segment.

Automotive Lightweight Materials Market By Application

· Body In White

· Chassis & Suspension

· Powertrain

· Interior

· Closures

· Others

Among the applications, the body in white segment is expected to lead the growth in the automotive lightweight materials market and contribute to 28.3% of the market size in 2023. This segment has emerged as the major growth driver because of the rising use of lightweight materials in cross and side beams, passenger compartment frames, underbody floors, front-end structures, and panels. This has underlined the importance of lightweight materials in improving vehicle efficiency and structural strength of the vehicle.

Automotive Lightweight Materials Market Regional Analysis

Europe has the biggest market share in the global automotive lightweight material market and has projected to have a CAGR of around 6% during the forecast period. The region enjoys the highest levels of market control due to strict environmental laws and emphasis on environmental conservation measures. Today’s challenging CO2 emission standards set by the European Union have led to extensive use of lightweight materials to enhance fuel economy and emissions. Europe is also inhabited by several key automotive manufacturers that are already experimenting with the application of new materials to conform to current standards and changing client preferences. Moreover, the region has well developed automobile production sector, which is focused on the usage of new technologies and innovations, as well as on research work. These endeavors seek to provide vehicles that are in harmony with the environmental requirements as well as containing new features which consumer’s desire.

The Asia-Pacific region, however, is quickly becoming the largest consumer of automotive lightweight materials as a result of the growing market for electric and hybrid vehicles. A number of countries like China, India, Japan and South Korea have unveiled their strategies to revolutionize their public transport through electric and advanced vehicles. Governments of the region have also put in place strict emission standards to counter increasing environmental issues due to increasing carbon footprint. These measures, regarding the restriction of undesirable effects on the natural environment, have established stringent emission requirements across numerous industries, such as automotive, which has in turn catalyzed demand for lightweight materials in the Asia-Pacific region.

Automotive Lightweight Materials Market Leading Companies

The Automotive Lightweight Materials market players profiled in the report is Alcoa Corporation, ArcelorMittal, BASF SE, LyondellBasell, Novelis Inc., Owens Corning, POSCO, Stratasys Ltd., Tata Steel, and Toray Industries, Inc.

Automotive Lightweight Materials Market Regions

North America

· U.S.

· Canada

Europe

· U.K.

· Germany

· France

· Spain

· Rest of Europe

Latin America

· Brazil

· Mexico

· Rest of Latin America

Asia-Pacific

· China

· Japan

· India

· Australia

· South Korea

· Rest of Asia-Pacific

Middle East & Africa

· GCC

· South Africa

· Rest of Middle East & Africa