Electric Vehicle Polymers Market Growth Opportunities and Forecast till 2032

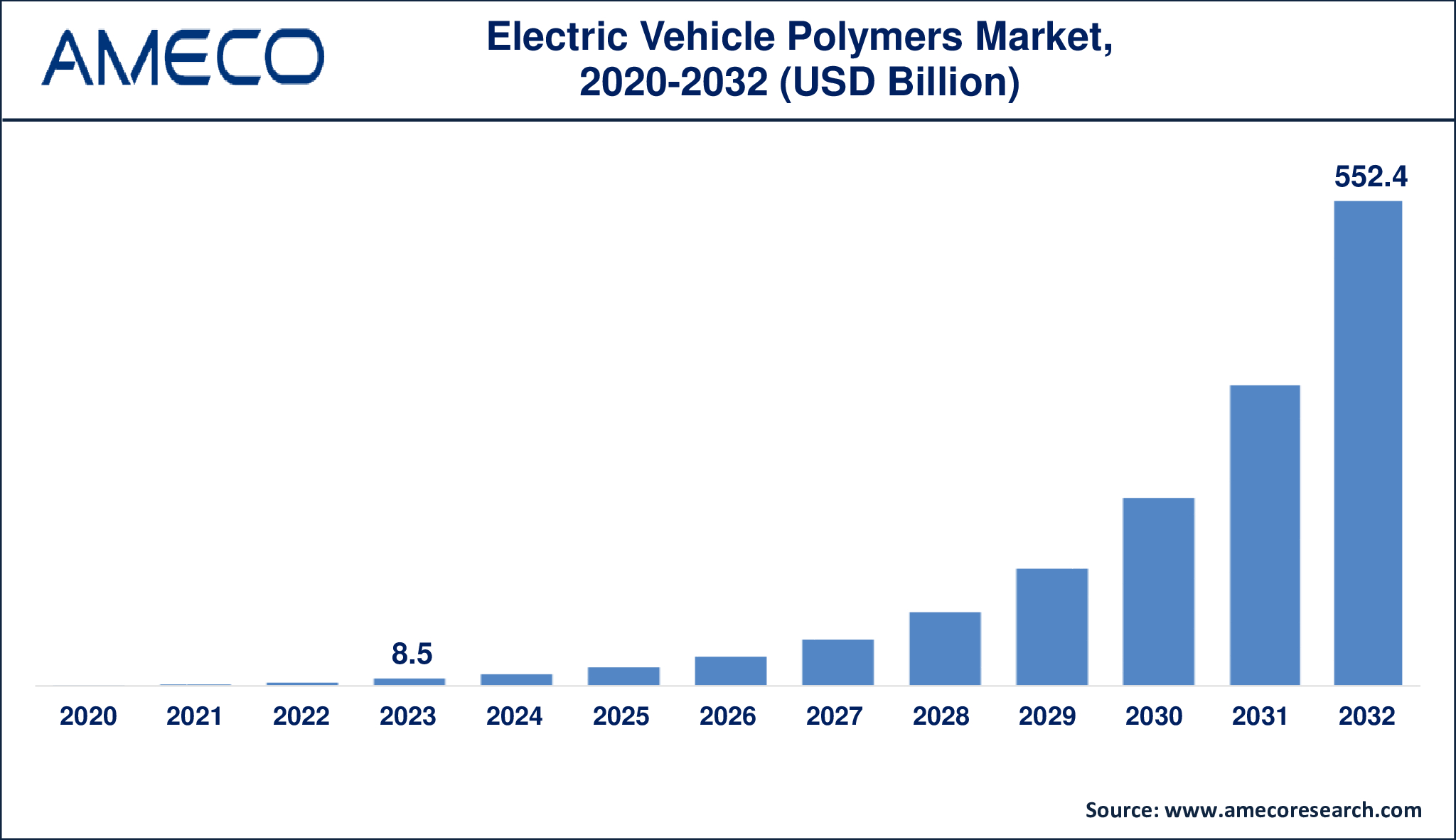

The Global Electric Vehicle Polymers Market Size was valued at USD 8.5 Billion in 2023 and is anticipated to reach USD 552.4 Billion by 2032 with a CAGR of 59.3% from 2024 to 2032.

Electric vehicle (EV) polymers represent advanced plastic materials which serve to replace traditional metal components in electric vehicles for improved efficiency, sustainability and performance. The wide range of EV applications includes interior components and battery enclosures and electric motor components where these polymers serve as key materials. Vehicle weight reduction through plastic substitution enables greater distance between charges and better energy efficiency. Modern thermoplastics provide outstanding heat resistance together with electrical insulation and mechanical strength which makes them suitable for high-performance EV components. E-mobility experiences a transformation through continuous polymer solution development which enables affordable manufacturing and offers innovative design possibilities such as 3D-printed vehicle components.

|

Parameter |

Electric Vehicle Polymers Market |

|

Electric Vehicle Polymers Market Size in 2023 |

US$ 8.5 Billion |

|

Electric Vehicle Polymers Market Forecast By 2032 |

US$ 552.4 Billion |

|

Electric Vehicle Polymers Market CAGR During 2024 – 2032 |

59.3% |

|

Electric Vehicle Polymers Market Analysis Period |

2020 - 2032 |

|

Electric Vehicle Polymers Market Base Year |

2023 |

|

Electric Vehicle Polymers Market Forecast Data |

2024 - 2032 |

|

Segments Covered |

By Component, By Type, By End User, and By Region |

|

Electric Vehicle Polymers Market Regional Scope |

North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

|

Key Companies Profiled |

Asahi Kasei Corporation, BASF SE, Celanese Corporation, Covestro AG, DuPont de Nemours, Inc., Evonik Industries AG, Kumho Polychem, Lanxess AG, LG Chem Ltd., Saudi Basic Industries Corporation, and Solvay. |

|

Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Regulation Analysis |

Electric Vehicle Polymers Market Dynamics

Electric vehicle polymers market growth receives substantial support from the increasing adoption of electric vehicles because of both emission regulations and fuel efficiency requirements. Lightweight materials improve both the distance which vehicles can travel along with the operational efficiency of batteries. The market grows due to cost-effective production methods and enhanced recyclability and improved thermoplastic applications in electric motors along with better production methods. The electric vehicle polymers market expands due to government sustainability programs and public entity initiatives regarding sustainable mobility. The recycling process for millions of end-life vehicles creates substantial environmental problems because the various materials in EVs make polymer recycling operations complicated. However, the electric vehicle polymers market encounters challenges from stringent government regulations because global efforts to promote recycling and because of high technology expenses along with facility requirements and EV polymer regulations. Market development faces new barriers because complying with changing environmental policies raises production costs. High-performance polymers used in EVs face potential growth barriers since sustainability concerns are increasing. Manufacturers must invest in innovative recycling methods and green polymer alternatives to surpass regulatory barriers in order to guarantee the sustained success of electric vehicle (EV) polymers market.

Furthermore, the growing EV polymers market encourages manufacturing plants to advance their automotive plastic processing methods. The industry shows improvements in molding techniques through injection and compression molding and resin transfer molding because high-performance polymers and composites have been replacing traditional materials. Manufacturers work to improve control systems for material handling and temperature management and curing processes to produce advanced lightweight components of high quality. The manufacturing sector gains higher efficiency through automated robotics systems and process control technologies which also enable strict adherence to quality standards. Automated systems together with in-mold process control solutions optimize production through the management of complex assembly operations and achieve better large-scale consistency and shorter production cycles. The EV polymers market evolution will strengthen the importance of high-performance polymers which will drive lightweighting, sustainability and cost-effectiveness in electric vehicle production.

Global Electric Vehicle Polymers Market Segment Analysis

Electric Vehicle Polymers Market By Component

· Powertrain System

· Exterior

· Interior

· Others

As per the electric vehicle polymers market forecast, the interior segment will demonstrate the strongest growth pattern during 2024 to 2032. The growing consumer interest in sustainable practices together with environmental considerations has increased the market demand for green interior components. Electric vehicles have become the preferred sustainable option over internal combustion engine cars because governments and consumers now prioritize carbon emission reduction and climate change response. The market demands lightweight durable environmentally friendly interior materials for electric vehicles which drives the need for high-performance polymers in the electric vehicle polymers market.

Electric Vehicle Polymers Market By Type

· Engineering Plastics

· Elastomers

· Others

As per the electric vehicle polymers industry analysis, the elastomers represent the leading segment as they deliver exceptional properties of elasticity and resilience together with versatile application capabilities. These polymers serve multiple EV functions due to their excellent sealing and insulating abilities by powering tire applications as well as gaskets and seals and suspension system components. The excellent durability properties of elastomers enhance energy efficiency by protecting vital EV components. Market expansion in electric vehicle manufacturing depends heavily on elastomers because these materials deliver reliable high-performance benefits which advance e-mobility technology.

Electric Vehicle Polymers Market By End User

· Plug-In Hybrid Electric Vehicles (PHEV)

· Hybrid Electric Vehicles (HEV)

· Fuel Cell Electric Vehicle (FCEV)

· Battery Electric Vehicles (BEV)

The electric vehicle polymers market predicts a stable CAGR trajectory for plug-in hybrid electric vehicle (PHEV) segment throughout the forecast period. The growing PHEV sales worldwide create substantial polymer market demand since these dual-power vehicles use both combustion engines and electric motors to provide fuel flexibility. PHEVs need polymers for their operation because they work with both standard fuels and battery-powered systems. The demand for carbon fiber-reinforced polymers continues to rise for PHEV interior and exterior components because these materials improve performance and decrease vehicle weight. The growing adoption of PHEVs, coupled with advancements in polymer applications, is expected to be a significant factor in shaping the future of the Electric Vehicle Polymers Market.

Electric Vehicle Polymers Market Regional Analysis

The electric vehicle polymers market shows Asia-Pacific as its leading market by controlling around 42% of the total share. The area leads in global electric vehicle production and consumption because it maintains a robust automotive manufacturing foundation together with friendly government regulations and increasing market interest in electric vehicles. The three leading electric vehicle markets are found in China and Japan together with South Korea because China currently holds the title as the world's biggest EV market. Powerful government policies in China such as tax incentives and emission regulations together with subsidies have driven EV adoption at a fast pace which creates robust market demand for high-performance polymers. The region benefits from strong supply chain operations because key polymer manufacturers and suppliers operate in the area which enables efficient production along with innovation in EV polymer technology.

The North America EV polymers market in shows strong expansion because of technological developments and the rising number of electric vehicle owners. The area attracts substantial investments toward polymer research which concentrates on developing materials that provide better durability along with thermal stability and lightweight properties and electrical conductivity to maximize vehicle performance and efficiency. EV adoption receives support from U.S. and Canadian governments through incentive programs and strict efficiency requirements and expanding charging networks which drives the market demand for advanced polymers. Automakers and polymer manufacturers operating in North America create conditions for next-generation material development including biodegradable polymers and self-healing plastics and high-strength composites which meet the changing requirements of the EV market.

The electric vehicle polymers market in Europe keeps expanding due to strict environmental regulations and carbon neutrality targets and rising electric vehicle market penetration. Through strict CO₂ emission regulations and EV subsidies the European Union works to speed up the replacement of internal combustion engine (ICE) vehicles with electric vehicles. Countries such as Germany, France, and the UK are investing heavily in lightweight materials and sustainable polymer solutions, ensuring compliance with evolving automotive regulations. Additionally, automakers in Europe are integrating recycled and bio-based polymers to align with circular economy initiatives, further boosting regional market growth.

Electric Vehicle Polymers Market Leading Companies

The electric vehicle polymers market players profiled in the report is Asahi Kasei Corporation, BASF SE, Celanese Corporation, Covestro AG, DuPont de Nemours, Inc., Evonik Industries AG, Kumho Polychem, Lanxess AG, LG Chem Ltd., Saudi Basic Industries Corporation, and Solvay.

Electric Vehicle Polymers Market Regions

North America

· U.S.

· Canada

Europe

· U.K.

· Germany

· France

· Spain

· Rest of Europe

Latin America

· Brazil

· Mexico

· Rest of Latin America

Asia-Pacific

· China

· Japan

· India

· Australia

· South Korea

· Rest of Asia-Pacific

Middle East & Africa

· GCC

· South Africa

· Rest of Middle East & Africa