Low Melting Fiber Market Analysis, Growth Opportunities, and Forecast 2023-2033

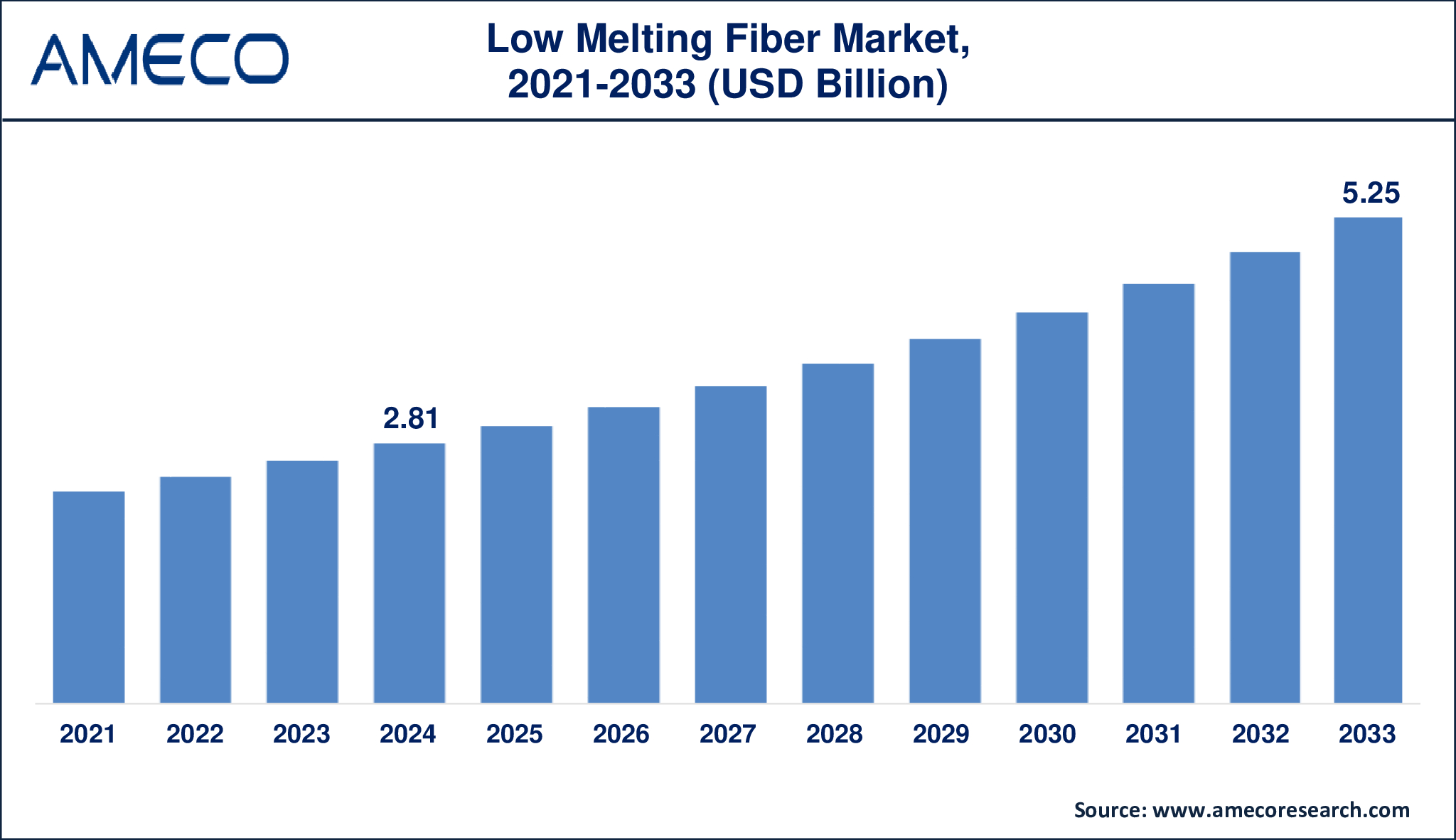

The Global Low Melting Fiber Market Size was valued at USD 2.81 Billion in 2024 and is anticipated to reach USD 5.25 Billion by 2033 with a CAGR of 7.2% from 2025 to 2033.

Low melting fiber (LMF) is a synthetic fiber that can melt at lower temperatures than ordinary polyester fibers, typically between 110°C and 180°C. It is primarily made out of two-component polymers, such as polyester or polyethylene, with a sheath-core structure. The external sheath melts after heat treatment, while the inner core remains structurally intact. This feature enables LMF to act as a binder in nonwoven fabrics, increasing durability and flexibility without the use of chemical adhesives. The most typical applications include automotive interiors, mattresses, filters, and insulation materials. Its eco-friendly bonding approach, which is free of toxic solvents, encourages sustainable production processes. Because of its strong thermal bonding properties, LMF is commonly used in industries that require lightweight, durable, and low-cost textile solutions.

|

Parameter |

Low Melting Fiber Market |

|

Low Melting Fiber Market Size in 2024 |

US$ 2.81 Billion |

|

Low Melting Fiber Market Forecast By 2033 |

US$ 5.25 Billion |

|

Low Melting Fiber Market CAGR During 2025 – 2033 |

7.2% |

|

Low Melting Fiber Market Analysis Period |

2021 - 2033 |

|

Low Melting Fiber Market Base Year |

2024 |

|

Low Melting Fiber Market Forecast Data |

2025 - 2033 |

|

Segments Covered |

By Type, By Application, And By Region |

|

Low Melting Fiber Market Regional Scope |

North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

|

Key Companies Profiled |

Eastman Chemical Company, Kolon Industries, Huvis, Toray Chemical Korea, Hickory Springs, Xianglu Chemical Fiber, Yangzhou Tianfulong, Nan Ya Plastics Fiber Visions Corporation, and Taekwang. |

|

Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Regulation Analysis |

Low Melting Fiber Market Dynamics

This low melting fiber market rise is primarily driven by increased acceptance in nonwoven applications in the bedding, automotive, and construction industries. The mattress sector has emerged as the major consumer, owing to increased demand from residential complexes, hotel infrastructure, and healthcare institutions that seek fire-resistant and thermally bonded materials.

The automotive industry, where LMF is increasingly used in seat padding, cabin insulation, and interior trims, has played a significant role in this upward trend. With a global push for fuel-efficient automobiles, LMF's lightweight and bonding qualities make it an important material for improving performance without increasing vehicle bulk. Furthermore, due to its thermal bonding capacity, LMF is gaining popularity in geotextile applications, making it critical for soil stabilization in construction projects, particularly in Asia and the Middle East.

Despite its rapid expansion, the market confronts hurdles. Price fluctuation in important raw materials like polyester and polypropylene can have an impact on manufacturers' profit margins. Additionally, environmental concerns surrounding the recycling and disposal of synthetic fibers are leading to regulatory pressures, especially in Europe. While sustainable alternatives are being researched, the infrastructure for recycling LMF remains limited in several developing economies.

Opportunities lie in the development of bio-based low melting fibers and advanced processing techniques that improve recyclability. Furthermore, as global infrastructure investments continue to rise and disposable incomes increase, particularly in Asia-Pacific and North America, the demand for high-quality bonded fibers in home textiles and furnishings is likely to expand steadily over the low melting fiber market forecast period.

Global Low Melting Fiber Market Segment Analysis

Low Melting Fiber Market By Type

· Melting Point ≤130

· Melting Point >130

According to our low melting fiber industry analysis, the market's main section is low melting fibers (melting point ≤130°C). These fibers are popular due to their superior bonding properties, improved mixing capabilities, and great resilience, making them appropriate for a variety of applications. Their ability to bond at lower temperatures enables more energy-efficient production, which is especially useful in companies striving to reduce carbon footprints. The eco-friendliness of these fibers fits with the expanding global emphasis on sustainable materials, driving up demand in a variety of sectors.

Fibers with melting points above 130°C are used in applications that require better heat resistance. While they have a smaller market share than their lower melting competitors, their use is vital in industrial operations that need higher temperature bonding. These fibers are commonly used in specialized automobile components and building materials that require high durability and heat resistance.

Low Melting Fiber Market By Application

· Mattress

· Bedding

· Padding

· Car Molding

· Others

The mattress segment is the most popular application for low melting fibers, accounting for the highest market share. The need is driven by the desire for comfortable, long-lasting, and sanitary bedding solutions. Low melting fibers allow great bonding without the need for chemical adhesives, resulting in mattresses that are both pleasant and environmentally sustainable. Their use improves the structural integrity of mattresses, providing more support and durability. The growing awareness of health and wellbeing, combined with the growth of the hotel and healthcare industries, has increased demand for high-quality mattresses, driving higher consumption of low melting fibers in this segment.

Low melting fibers are utilized in bedding items like as pillows, comforters, and mattress toppers. Their ability to deliver softness while maintaining shape over time makes them perfect for certain applications. The increased consumer preference for hypoallergenic and easy-to-maintain bedding products has prompted producers to integrate low melting fibers, which enhance the overall comfort and longevity of bedding items.

Low Melting Fiber Market Regional Analysis

The Asia-Pacific region dominates the worldwide LMF market, owing mostly to China's large-scale manufacturing capability and consumption, which generates over 20 million tons of polyester fibers per year while also importing considerable volumes to fulfill expanding demand in local industries. Applications such as mattress manufacturing, nonwoven carpet layers, automotive interiors, and geotextiles are expanding rapidly in nations like India, Japan, South Korea, and Vietnam due to ongoing urbanization and housing development programs.

China continues to maintain a leadership position, aided by favorable government policies supporting textile exports, as well as infrastructure-focused initiatives like the Belt and Road Project, which fuels demand for construction textiles and insulation materials. India also offers promise, with the Ministry of Textiles emphasizing increasing investment in technological textiles under the National technological Textile Mission.

Another key region is North America, which is predicted to grow at an 8.1% CAGR until 2033. The biggest demand drivers in the United States are home furnishings, mattresses, and the automotive sector, which uses LMF in seat cushions, headliners, and trunk insulation. Rising consumer focus on interior comfort, combined with house refurbishment trends, is driving market penetration.

Meanwhile, Europe's growth is consistent, fueled by environmental legislation and customer demand for eco-friendly home textile solutions. Government assistance for green materials, as well as increased acceptance of LMF in real estate refurbishments, has made nations such as Germany and France active participants in the regional market.

Low Melting Fiber Market Leading Companies

The low melting fiber market players profiled in the report is Eastman Chemical Company, Kolon Industries, Huvis, Toray Chemical Korea, Hickory Springs, Xianglu Chemical Fiber, Yangzhou Tianfulong, Nan Ya Plastics Fiber Visions Corporation, and Taekwang.

Low Melting Fiber Market Regions

North America

· U.S.

· Canada

Europe

· U.K.

· Germany

· France

· Spain

· Rest of Europe

Latin America

· Brazil

· Mexico

· Rest of Latin America

Asia-Pacific

· China

· Japan

· India

· Australia

· South Korea

· Rest of Asia-Pacific

Middle East & Africa

· GCC

· South Africa

· Rest of Middle East And Africa